Optimized automated X-ray and CT quality inspections

Cheetah EVO responds to the need for improved, automated operation with integrated workflows in the FGUI operating software. The Comet Yxlon FF CT software is designed to start automatically for faster reconstruction and visualization. It has a unique ability to render 3D cinematic images with a preset selection of transfer functions (TF), resulting in the most realistic, vivid visualization available today.

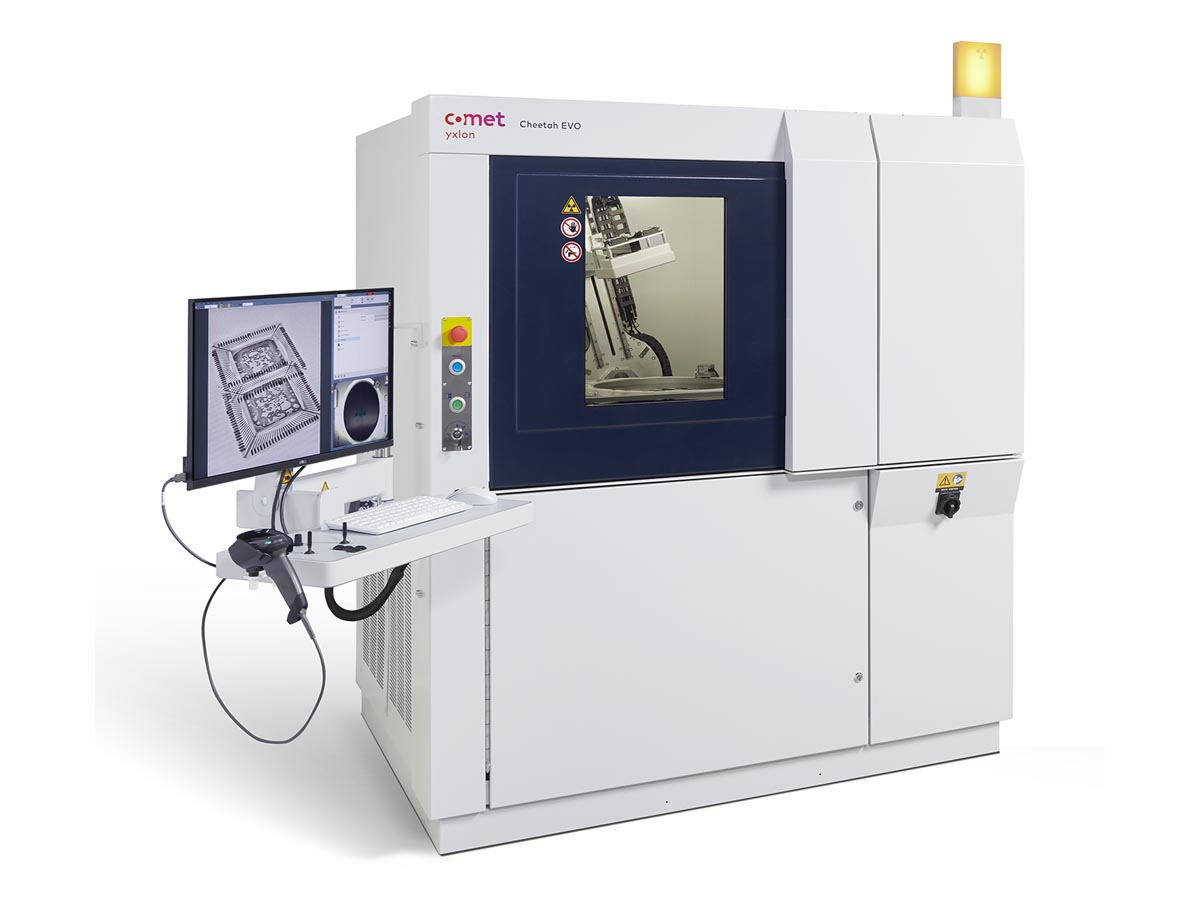

The Cheetah EVO is designed to meet the demands of Industry 4.0, enabling efficient and reliable inspection in the SMT and semiconductor industry as well as in laboratories.

Cheetah EVO

Series:

CC series

Industry:

Automotive, Electronics, Aerospace, Science & research, Semiconductors

Defect size:

<µm Defect, <50µm Defect, <1mm Defect, >1mm Defect

Part Size:

Small Size, Medium Size

Mode of operation:

2D, 3D, 2D/3D

Cheetah EVO highlights

Reliable, fast, and repeatable inspections – manually and automatically

Automatic void calculation with VoidInspect

Easy-to-use, dynamic enhancing filters, e.g., eHDR

Best available laminography with micro3Dslice and FF CT software

Dose reduction kit and low dose detector mode for sensitive components

Optional high load capacity (< 20 kg)

Optimized automated X-ray and CT quality inspections

Cheetah EVO responds to the need for improved, automated operation with integrated workflows in the FGUI operating software. The Comet Yxlon FF CT software is designed to start automatically for faster reconstruction and visualization. It has a unique ability to render 3D cinematic images with a preset selection of transfer functions (TF), resulting in the most realistic, vivid visualization available today.

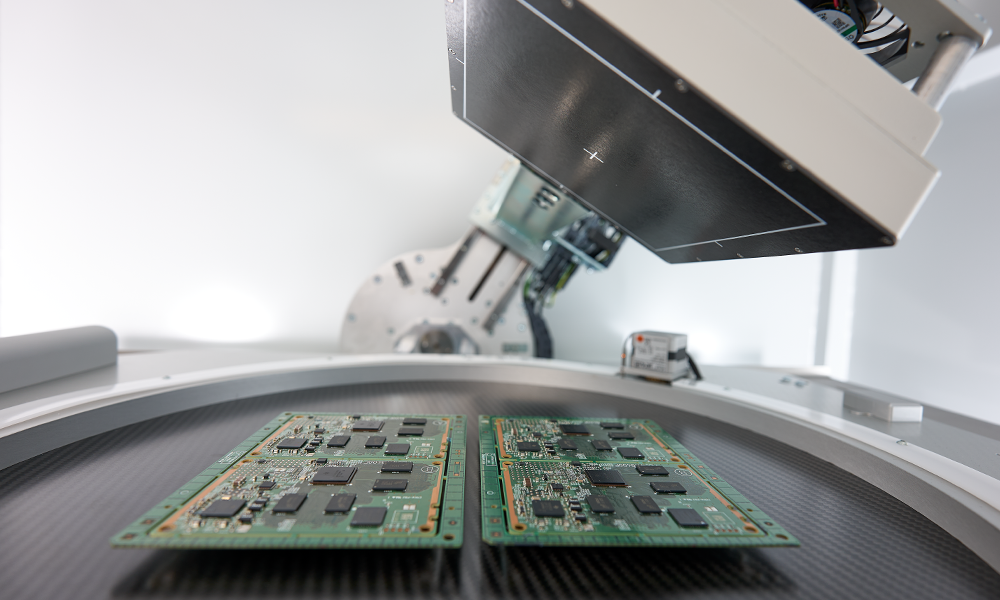

SMT inspections: grand performance for small devices

Due to the continuous miniaturization of electronic components, more and more features must fit in an ever-smaller area. For the most accurate and repeatable quality inspection results, a test system must not only provide high performance and resolution but also needs to be equipped with dynamic image enhancement filters. The Comet Yxlon Cheetah EVO features:

Large flat-panel detectors with up to 50% larger field of view for a better overview and faster working processes due to reduced steps in automated processes

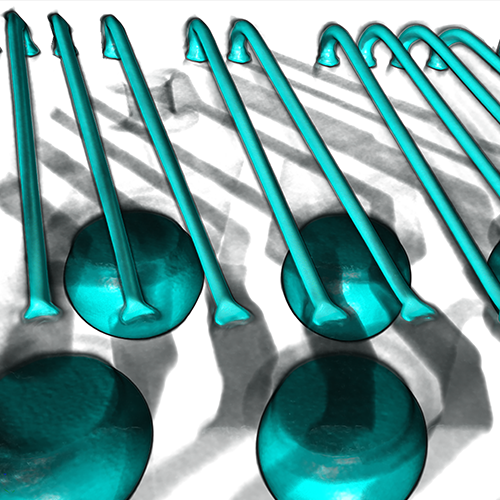

Best laminography with micro3Dslice, with detailed 3D visualization for quick and easy failure analysis – resulting in substantial cost-savings compared to micro sectioning

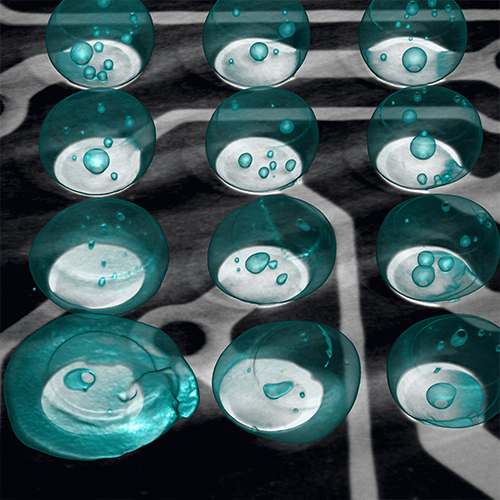

Automatic void calculation with VoidInspect, the laminography-based inspection workflow enabling the rapid non-destructive analysis of voids inside the solder joints of board components

Integration in the production line: ProLoop (Link auf Video weiter unten) allows direct communication with inline AOI / AXI inspection systems

Optional high load capacity (< 20 kg) with reinforced table and mechanics: Several parts and electronic interconnects in fixed packages can be inspected at once – a real-time saver

Cheetah EVO SMT applications

PCB

BTC | BGA | LGA | QFN/QFP | THT

IGBT

LED

Semicon inspections: maximum resolution at minimum voltage

Electronic components and semiconductor devices are the key elements of most electronic systems. Due to their compactness and density, testing requires maximal image resolution at low power and low voltage. Void compilations, including multi-area voiding, need accurate, repeatable inspection routines. The Comet Yxlon Cheetah EVO offers:

Highly sensitive detector with optional low dosage mode

High detail recognition through an integrated image chain

Integrated, automatic defect detection with FGUI (e.g. voids in bumps)

Cheetah EVO semiconductor applications

Wafers and integrated circuits (IC)

Die attach connections | 3D IC joints | TSV

Sensors

MEMS and MOEMS

Laboratory inspections: leading technology for precise analysis

The inspection of electronic components during research and development is highly complex and requires a broad range of features. Computed tomography with the Comet Yxlon Cheetah EVO is the technology of choice for detailed analyses of micro components such as those used in batteries, connectors, and medical devices.

Exceptional CT quality due to a range of highly sensitive detectors with excellent contrast-to-noise ratio

Realistic, vivid visualization by Comet Yxlon FF CT software, integrated with the FGUI user interface workflows with individual 3D cinematic renderers, artifact reduction, and a preset selection of transfer functions (TF)

Cheetah EVO lab applications

Batteries

Connectors

Various hard-to-see electronics components

Medical material

Military and space electronics

Technical Data

| Attribute | Respective Value |

| Sample Size | 800 x 500 [mm] (31'' x 19'') |

| Max. Radiographic Area | 460 x 410 [mm] (18'' x 16'') |

| System Dimensions (W/D/H) | 1650 x 1400 x 2050 [mm] |

| System Weight | 2200 kg |

| FeinFocus X-ray Tube | FXT-160.50 Microfocus or FXT-160.51 Multifocus, 20 - 160 kV voltage range |

| Detector Active Area | 1004 x 620 px (Y.Panel 1308), 1004 x 1004 px (Y.Panel 1313), 1276 x 1276 px (ORYX 1616) |

| Pixel Pitch | 127 µm |

| Bit Depth | 16 bit |

| Oblique Viewing | +/- 70° (140°) |

| 3D Modes | Laminography (micro3Dslice), CT Quick Scan, Quality Scan |